Biosphere 2

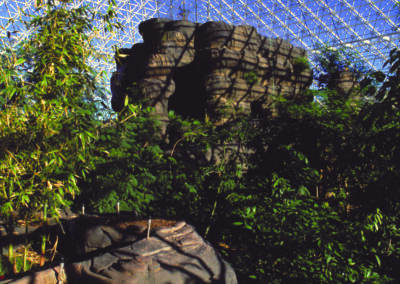

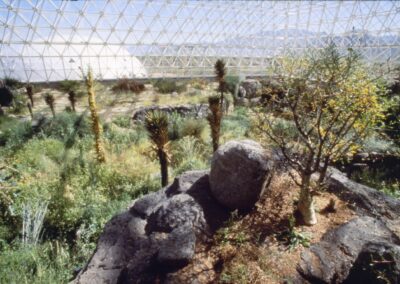

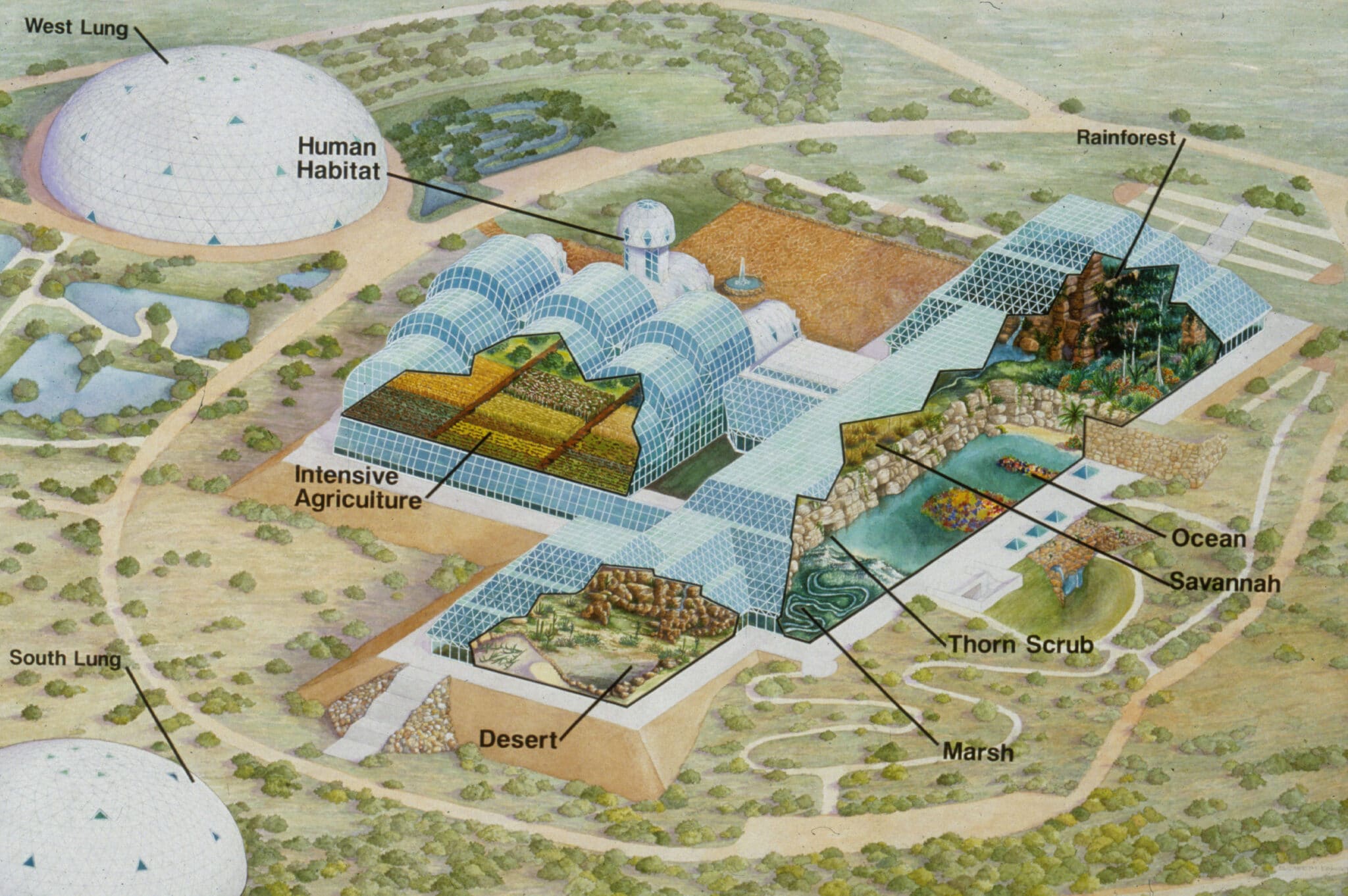

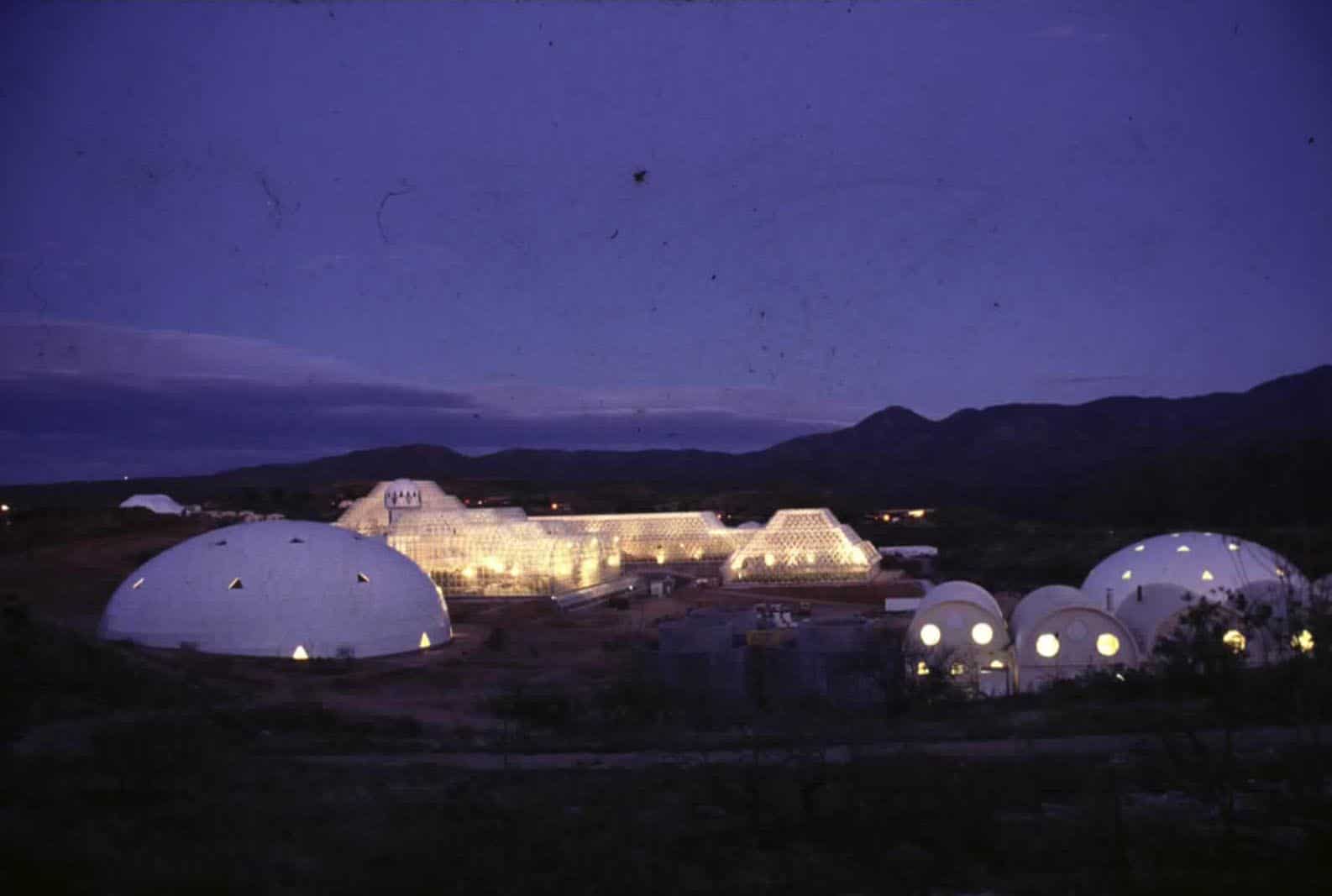

Oracle, ArizonaContained within a magnificently designed air-tight glass and steel frame structure, Biosphere 2 covered three acres of Arizona desert and included models of seven biomes: an ocean with coral reef, a marsh, a rainforest, a savannah, a desert, farming areas and a micro-city. Eight people lived inside this structure for two years (1991-1993) and set world records in human life support, monitoring their impact on the environment, while providing crucial data for future manned missions into outer space.

Project Overview

Biospheric Design’s most famous design project is the Biosphere 2 Project, a magnificent laboratory for the study of global ecology. This 3.15 acre miniature airtight world is sealed on the bottom by a stainless steel liner and on the top by a steel and glass space frame structure. Inside the laboratory is a 850-square meters coral reef, a 450 square meters mangrove marsh, a 1,900 square meters Amazonian rainforest, a 1,300 square meters savannah grassland, a 1,400 square meters fog desert, a 2,500 square meters tropical agriculture system with farm, & a human habitat with living quarters, offices, & recreational spaces. Heating and cooling water circulated through the biosphere in independent piping systems, & electrical power was supplied to the Biosphere from a natural gas energy center, located outside Biosphere 2, through airtight penetrations.

- The eight-member crew set a new world record for the amount of time spent living in a closed system by surpassing the previous record (six months) held by Russian researchers in the Bios-3 experiment.

- The facilities’ annual air-leak rate of less than 10 percent is the lowest leak rate of any such structure ever built. (NASA’s closed-system facility at Kennedy Space Center leaks 10 percent a day). The tight seal enabled the detection of an oxygen decline, which has led to significant research about oxygen cycles.

- The crew produced approximately 80 percent of its food, setting another world record for food production in a closed system, despite two winters of record high rainfall and cloudy weather. The remaining approximately 20 percent was provided from seed stock and from crops grown and stored in Biosphere 2 prior to closure. The crops were produced without the use of toxic pesticides or chemical fertilizers.

- The ocean system was the largest artificial coral reef in the world and sustained over 800 coral colonies with 87 new baby colonies formed during the two years.

100% of domestic animal wastes were processed.

100% of human wastes were processed.

100% of utility and drinking water was recycled.

100% of wilderness utility & ground water was recycled.

100% of the ocean and marsh water was recycled.

Recent Publications

Life Under Glass: Crucial Lessons in Planetary Stewardship from Two Years in Biosphere 2, Abigail Alling, Mark Nelson, Ph.D, and Sally Silverstone. The only account written by the team while enclosed inside Biosphere 2, telling the story of how they lived and worked there for two years. Available through Synergetic Press in a new second edition, here.

Pushing Our Limits, Mark Nelson, Ph.D. Pushing Our Limits offers a fresh examination of Biosphere 2, from one of the original biospherians, now twenty-five years after its first closure experiment. Available from Synergetic Press, here.

Awards and Recognitions

Biosphere 2 was nominated by the USA Discovery Channel in 2003 as the #3 greatest engineering achievement in the 20th Century. Biosphere 2 was also the winner of the 1992 Gold Nugget Award for Best Architectural Design, its energy center received a merit award from Pacific Coast Builders for Best Industrial Project, it was honored as one of Time Magazine’s Top Ten Scientific Projects in 1993, and Biosphere 2 was featured by Columbia University for its contributions to ongoing ecological science.

“Artificial biospheres to a biospheric scientist or an ecological engineer have all the relevance of a cyclotron to a physicist, a wind tunnel to an aerodynamicist, or a clinic to a physician.”

– John Allen, Inventor, Biosphere 2